Bottling

Solid, scalable solution for your business model

Our Bottling Solutions

We are specialized in small, medium and large mobile (40 ft. container), water bottling and packaging systems. Large units are capable of filling up to 2,800 bottles per hour (1.5 liter size). These innovative water filling plants operate on site and are energy self-sufficient (if desired). The plant is capable of performing various operations: loading preforms, stretch mould bottle blowing, filling, capping, labelling, coding.

Small

- semi-automatic

- output capacity: up to approx. 700 bph

- bottle volume: 0.2 - 2.0 Liter (with 2 cavity)

- blowing pressure 15 bar

also available as mobile container unit

Medium

- automatic

- output capacity: up to approx. 1400 bph*

- bottle volume: 0.2 - 2.0 Liter*

- blowing Pressure 15 bar

also available as mobile container unit

Large

- automatic

- output capacity: up to approx. 3000 bph*

- bottle volume: 0.2 - 2.0 Liter*

- blowing Pressure 15 bar*

also available as mobile container unit

*others on request

The Technology

A short summary about the technology behind our bottling solution.

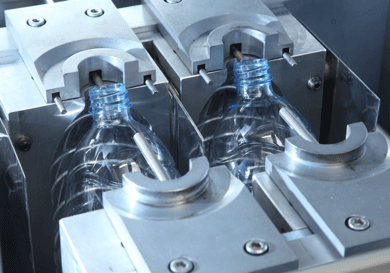

Step 1: PET-Bottle Blowing

Fully automatic, energy saving (15 bar air blowing pressure), PET-bottles production delivers complete solutions incl. preforms. Bottle shape and size tailored to customer’s needs.

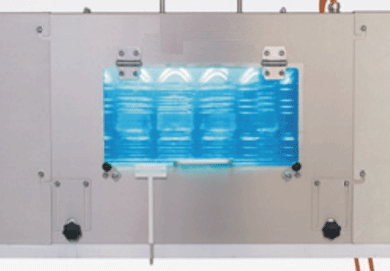

Step 2: UV-Tunnel

A surface disinfection is performed with the aid of UV-light treatment before bottles are filled.

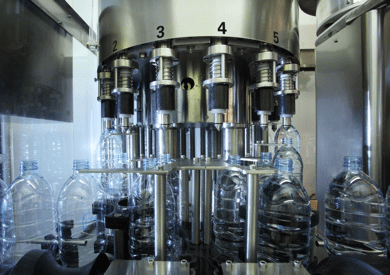

Step 3: Bottle filling

Fully automatic bottle filling for standard size, 0,5 to 1,5 Liter bottles. Larger container sizes, ie. Gallon, are possible per request.

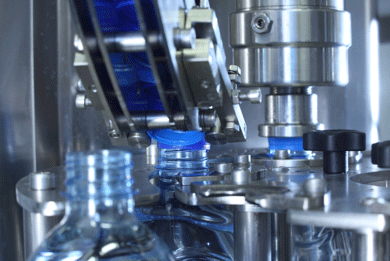

Step 4: Capping

Fully automatic capping of bottles directly after filling prevents potential outside contamination.

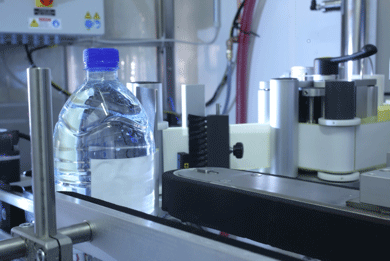

Step 5: Labeling

Fully automatic labeling of filled and capped bottles with self-adhesive labels. Versatile label design possible according to customer’s needs.

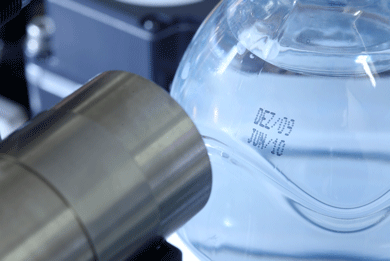

Step 6: Date Printing

Bottles are automatically stamped with current date, expiration date, etc. information directly after labelling process.

Do you have any questions about the technology? We will be happy to advise you.

Contact

Small, mobile and easy to operate

Bottling Solution for NGO's and Water Kiosks

For "smaller" applications we offer semi-automatic solutions capable of bottle rinsing, filling and capping. These are designed especially for filling 1,0 and 1,50 Liter bottles oder gallon containers (19 Liters), and are ideal for decentralized drinking water supplies and refinancing of infrastructure investment projects through sale of safe drinking water (Help - Helping others help themselves). Our system is capable of delivering 5000 L/day (i.e. 250 gallons at 19 Liters each) during a 6 hour operations period. New and recycled bottles (uniform in size and shape) can be used, since our system has an integrated rinsing capability before the bottles are filled and sealed, and undergo UV-disinfection process.